Mounting bearings using heat |

The force needed to mount a bearing increases rapidly with bearing size. Because of the mounting force required, larger bearings cannot easily be pressed onto a shaft or into the housing. Therefore the bearing or the housing is heated before mounting. |

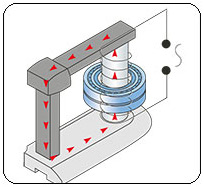

Principle of induction heating

An induction heater can be compared to a transformer using the principle of a primary coil with a large number of windings, and a secondary coil with a few windings, on a mutual iron core. The input/output voltage ratio is equal to the ratio of the windings, while the energy remains the same. Consequently, the secondary coil will provide a low voltage at high amperage. In the case of the SKF induction heater, the bearing is a short circuited, single turn, secondary coil through which a low A.C. voltage flows at high amperage, thus generating high heat. The heater itself, as well as the yoke, remains at ambient temperature. As this type of heating induces an electric current, the bearing will become magnetized. It is important to ensure that the bearing is then demagnetized so that it will not attract metal particles during operation. All SKF induction heaters have automatic demagnetizing cycles. An induction heater can be compared to a transformer using the principle of a primary coil with a large number of windings, and a secondary coil with a few windings, on a mutual iron core. The input/output voltage ratio is equal to the ratio of the windings, while the energy remains the same. Consequently, the secondary coil will provide a low voltage at high amperage. In the case of the SKF induction heater, the bearing is a short circuited, single turn, secondary coil through which a low A.C. voltage flows at high amperage, thus generating high heat. The heater itself, as well as the yoke, remains at ambient temperature. As this type of heating induces an electric current, the bearing will become magnetized. It is important to ensure that the bearing is then demagnetized so that it will not attract metal particles during operation. All SKF induction heaters have automatic demagnetizing cycles. |

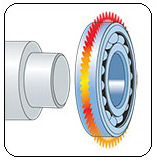

Hot mounting

The temperature difference between the bearing and seating depends on the magnitude of the interference fit and the bearing size. Normally a bearing temperature of 80 to 90 °C (144 to 162 °F) above that of the shaft is sufficient for mounting. Never heat a bearing to a temperature greater than 125 °C (257 °F), because the material may change metallurgically and produce alterations in diameter or hardness. Local overheating must be avoided and in particular never heat a bearing using an open flame. Wear clean protective gloves when mounting a hot bearing. Lifting (hoisting) gear can facilitate mounting. Push the bearing along the shaft as far as the abutment and hold the bearing in position, pressing until a tight fit is obtained. The temperature difference between the bearing and seating depends on the magnitude of the interference fit and the bearing size. Normally a bearing temperature of 80 to 90 °C (144 to 162 °F) above that of the shaft is sufficient for mounting. Never heat a bearing to a temperature greater than 125 °C (257 °F), because the material may change metallurgically and produce alterations in diameter or hardness. Local overheating must be avoided and in particular never heat a bearing using an open flame. Wear clean protective gloves when mounting a hot bearing. Lifting (hoisting) gear can facilitate mounting. Push the bearing along the shaft as far as the abutment and hold the bearing in position, pressing until a tight fit is obtained. |

|

|

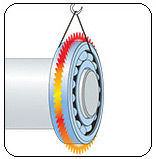

Lifting gear |

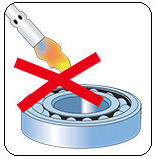

Never heat a bearing using

an open flame |

|

Reliability Direct, Inc. supplies a full range of heating tools, such as induction heaters and electric plates with an adjustable thermostat and cover for all common mounting needs.

Link to bearing heater offering:

http://www.reliabilitydirectstore.com/Induction-Bearing-Heaters-s/90.htm |

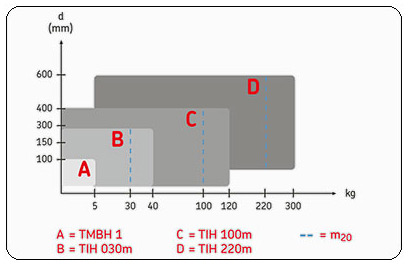

SKF m20 concept

“m20” represents the weight (kg) of the heaviest SRB 231 bearing which can be heated from 20 to 110 °C (68 to 230 °F) in 20 minutes. This defines the heater’s power output instead of its power consumption. |

Selection guide

There are no totally restrictive guidelines to follow when choosing your SKF bearing heater. It will depend upon the type and geometrical dimensions of the components you want to heat. Nevertheless, Reliability Direct, Inc. offers the following helpful general selection guide for SKF Bearing Heaters. |

|