|

|

You are here: Knowledge Base > Lubrication

|

Lubrication - Glossary of lubrication terms Last Updated: 05/02/2013 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Maintenance knowledge: Lubrication - Glossary of lubrication termsThickener or soap Thickener or soap is the system, which holds the oil and/or additives together to enable the lubricating grease to function. The thickener system is formed from either soaps or non–soaps. The type of thickener gives the grease its typical characteristics. Soaps are based on lithium, calcium, sodium, barium, or aluminium. Non–soaps are based on organic or non–organic solids, bentonite clay, polyurea, silica gel. Thickener compatibility chart

Note: SKF high performance, high temperature bearing grease LGHP 2 is not a common polyurea type grease. It is a di–urea bearing grease, which has successfully been tested for compatibility with lithium and lithium complex thickened greases i.e. LGHP 2 is compatible with such greases.

Base oil The base oil is the oil inside the grease, which provides the lubrication under the operating conditions. Greases are normally based on mineral oils. Synthetic oils can be used for very specific applications such as extremely high or low temperatures. The base oil generally constitutes more than 70% of a grease’s composition. Base oil compatibility chart

Base oil viscosity Viscosity is a measure of a fluid’s flow characteristics and is usually expressed in terms of the time required for a standard quantity of the fluid, at a given temperature, to flow through a standard orifice. Since viscosity decreases with increasing temperature, the temperature at which it is measured is always stated. The viscosity of base oils is always indicated as a kinematic viscosity abbreviated to cSt, at 40 °C and often also at 100 °C. Additives Additives are used to provide additional characteristics such as wear and corrosion protection, friction reducing effects and preventing damage under boundary and mixed lubrication conditions. Grease consistency/penetration A measure of the stiffness of a grease. The consistency is classified according to a scale developed by the NLGI (National Lubricating Grease Institute). This is based on the degree of penetration achieved by allowing a standard cone to sink into the grease at a temperature of 25 °C for a period of five seconds. The depth of penetration is measured on a scale of 10-1 mm and the softer greases allow the cone to penetrate further into the grease, hence the higher penetration number. The test method is in accordance to DIN ISO 2137. Classification of greases by NLGI consistency number

DIN 51825 Classification system

Bearing greases can be classified according to DIN 51825. The explanation of the DIN code KP2G-20 is given in the below tables. DIN 51825 for example: K P 2 G - 20 Application area

Third designation letter Letter

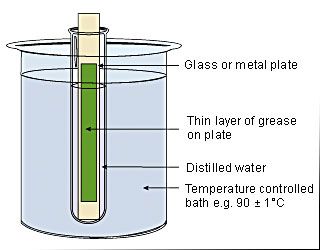

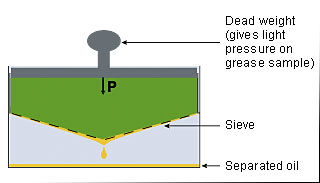

Drop point The drop point is the temperature at which the grease sample, when heated, will begin to flow through an opening and is measured according to DIN ISO 2176. The drop point does not relate to the allowable operating service temperature of the grease. Mechanical stability The consistency of a rolling bearing grease should not alter, or only slightly, during the working life of the rolling bearing. Depending on the application, the following tests can be relevant to evaluate the mechanical stability of a grease. Prolonged penetration The grease sample is filled into a cup and using an automatic device (called a grease worker) subjected to 100 000 double strokes. At the end of the test the penetration of the grease is measured. The difference between the measured penetration at 60 strokes and after 100 000 strokes penetration is reported as the change in 10-1 mm Roll stability The change in the grease structure (amount of softening or hardening) can be evaluated by filling a cylinder with a pre–specified quantity of grease. A roller is placed inside the cylinder and the complete unit is rotated for 2 hours at room temperature in accordance with ASTM D 1403. SKF modified the standard test procedure to reflect the application conditions under which the grease is used to either 72 or 100 hours at a test temperature of 80 or 100 °C. At the end of the test period the cylinder is allowed to cool to room temperature and the penetration of the grease is measured. The difference between the original penetration and the value measured is reported as the change in penetration in 10-1 mm. SKF V2F test The candidate grease is tested for mechanical stability using the following procedure. The test rig consists of a railway axlebox subjected to vibration shocks of 1Hz from a bouncing hammer producing an acceleration level between 12 – 15 g. The test is run at two different speeds, 500 and 1 000 rpm. If the grease, which leaks from the housing through the labyrinth seal which is collected in a tray after 72 hours at 500 rpm, weighs less than 50 grams the test is continued for a further 72 hours at 1 000 rpm. If the total amount of grease leakage after both tests (72 hours at both 500 and 1 000 rpm) does not exceed 150 grams then a rating of ‘M’ is given. If the grease only fulfils the first part of the test (72 hours at 500 rpm with a grease leakage of 50 grams or less) but fails the second stage, a rating of ‘m’ is given. If the grease leakage after 72 hours at 500 rpm is greater than 50 grams then it is rated a ‘fail’. Corrosion protection Lubricating greases should protect metal surfaces from corrosive attack in service. The corrosion protection properties of rolling bearing greases are evaluated using the SKF Emcor method, which is standardised under ISO 11007. Under this test method a mixture of lubricating grease and distilled water is present in the bearing. The bearing alternates during a defined test cycle between standstill and rotation at 80 rpm. At the end of the test cycle the degree of corrosion is evaluated according to a scale between 0 (no corrosion) and 5 (very severe corrosion). A more severe test method is to use salt water to replace the distilled water following the standard test procedure. In addition the test can also be carried out by continuously allowing water to flow or wash through the bearing arrangement during the test cycle. This test method is called the SKF Distilled Water Washout Test. The evaluation procedure is exactly the same as that used under the standardised method. However the procedure places greater demands on the corrosion protection properties of the grease. Copper corrosion Lubricating greases should protect copper alloys used in bearings from corrosive attack while in service. The copper corrosion protection properties of rolling bearing greases are evaluated using the standardised method DIN 51811. A copper strip is immersed in the grease sample and placed in an oven. The strip is then cleaned and the degradation is observed. The result is rated by a numerical system. Water resistance The water resistance of lubricating greases is measured in accordance with DIN 51 807 part 1. A glass strip is coated with the candidate grease, which is placed into a water–filled test tube. The test tube is immersed in a water bath for three hours at a specified test temperature. The change in the grease is evaluated visually and reported as a value between 0 (no change) and 3 (major change) along with the test temperature. Test for water resistance of greases  DIN 51 807: rating for degree of grease deterioration in water Oil separation Lubricating greases release oil when stored for long periods of time or when used in bearings as a function of temperature. This phenomenon is necessary to ensure good lubrication. The degree of oil separation will depend upon the thickener, base oil and manufacturing method. A cup is filled with a given quantity of grease (which is weighed before the test) and a 100 gram weight placed on top of the grease. The complete unit is put into an oven at 40 °C for one week. At the end of the week the amount of oil, which has leaked through the sieve is weighed and reported as a percentage of weight loss. The amount of oil separation is measured in accordance with DIN 51 817. Test for oil bleeding rate  DIN 51 817: determination of the % oil separated after one week at 40 °C Lubricating ability

The SKF R2F machine assesses the high temperature performance and lubricating ability of a grease, simulating the conditions under which large size bearings operate in housings. The test method is carried out under two different conditions. Test A is conducted at ambient temperature and Test B is conducted at 120 °C. A pass rating in the unheated test (Test A) means that a grease can be used to lubricate larger rolling bearings at normal operating temperatures and also in low vibrating applications. A pass in the heated test (Test B) at 120 °C means that the grease is suitable for use in large roller bearings operating at elevated temperatures. Rolling bearing grease life The SKF R0F grease test machine determines the grease life and high temperature performance limit of a lubricating grease. Ten deep groove ball bearings are fitted into 5 housings and filled with a given quantity of grease. The test is undertaken at a pre–determined speed and temperature. Both an axial and radial load is applied and the bearings run until failure. The time to failure is recorded in hours and a Weibull life calculation is made at the end of the test period to establish the grease life. This information can then be used in the determination of re–lubrication intervals in an application. EP performances The 4–ball weld load test. This method evaluates the EP (Extreme Pressure) performance of a lubricating grease. This test method is standardised under DIN 51 350/4. Three steel balls are held in a cup and another fourth ball is rotated against the three balls at a given speed. A starting load is applied and increased at predetermined intervals until the rotating ball siezes and welds to the three stationary balls. The test indicates the point at which the extreme pressure limit of the grease is exceeded. Greases can be considered as EP greases when the weld load is higher than 2600 N. The 4–ball wear scar test This test is performed with the same rig used in the 4–ball weld load test. 1400 N are applied on the fourth ball during 1 minute. Then the wear on the three balls is measured. Standard test uses a load of 400 N. However, SKF has decided to increase that to 1400 N in order to make the test relevant for bearing applications. False Brinelling Anti–fretting properties of a grease can be relevant for certain applications. SKF can assess these properties using the FAFNIR test standardised as ASTM D4170. Two ball thrust bearings are loaded and oscillated. The wear on each bearing is then measured. Greases offer good fretting protection when the measured wear is below 7 mg.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||