|

The

perfect solution for every application

|

|

Courtesy of SKF Maintenance Products

|

|

Even the very best bearing can only show optimum performance

when it is lubricated correctly. Here, it is extremely important to choose

the right bearing grease and to apply the most suitable lubrication intervals

and methods. This realization has prompted SKF, the world's leading

manufacturer of rolling bearings, to look intensively into the subject of

lubrication. SKF engineers consider grease to be a "fundamental"

component of the bearing arrangement and thus, as important as the bearing,

housing and sealing. SKF's vast experience in the development of rolling

bearings forms the basis for the development of a special range of

lubricants, the superior quality of which is obtained through continuous

testing and studies.

The strict standards and testing parameters developed and

applied at the SKF Engineering and Research Center have become

internationally recognized benchmarks for bearing greases. The comprehensive

range of SKF bearing greases is the result of many decades of research and development.

Each individual lubricant is precisely adjusted to the respective field of

application.

|

|

|

|

|

|

|

SKF sets the standard

Tangible performance parameters mean more to SKF than the

chemical composition of the lubricant. The chemical composition is not the

only factor in determining the quality of a particular grease, since modern

lubricants are extremely complex. SKF has set the standards for developing

special testing parameters.

|

|

|

Bearing grease selection

Incorrect lubrication accounts for up to 36 % of premature

bearing failures. All–purpose greases are inadequate for specialized bearing

needs and can cause problems rather than be beneficial. Bearing applications

have wide variations of operating conditions and correct lubrication calls

for matching the grease precisely to the application.

|

|

|

|

Bearing greases help ensure smooth, trouble–free operation and

maximum reliability even under the most extreme conditions. They help prevent

contamination from penetrating the bearing, cushion any shock loads and

protect against corrosion. Selecting the right bearing grease for a certain

application is essential for achieving the maximum service life of a bearing.

|

|

|

|

Selection criteria for correct lubrication include bearing

type and size, temperatures, speeds and loads, as well as the desired service

life and re–lubrication intervals.

|

|

|

|

|

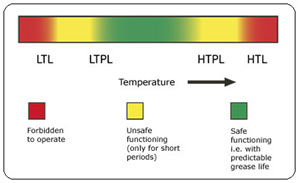

SKF Traffic light concept and Grease Performance Factor

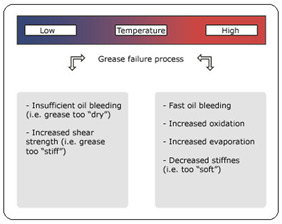

The temperature range over which a grease can be used depends

largely on the type of base oil and thickener used as well as the additives.

The relevant temperatures are schematically illustrated in the following

diagrams in the form of a “double traffic light”.

|

|

|

Operating temperature range of greases:

The SKF Traffic Light Concept

|

|

|

|

|

|

|

|

LTL – Low–temperature limit:

The lowest temperature at which the grease will allow the

bearing to be started up without difficulty.

LTPL – Low–temperature performance limit:

Below this limit, the supply of grease to the contact surfaces

of rolling elements and raceways may become insufficient. Values are

different for roller and ball bearings.

HTPL – High–temperature performance limit:

Above this limit the grease will oxidize in an uncontrolled

way, so that grease life cannot be determined accurately.

HTL – High–temperature limit:

When exceeding this limit, the grease loses its structure

permanently (e.g., the dropping point for soap–base greases).

|

|

|

|

|

|

|

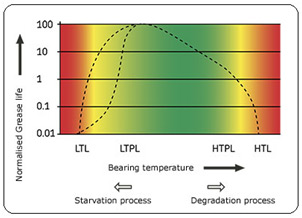

Effect of temperature on grease functioning

|

|

The values shown in these diagrams are based on extensive

tests conducted in SKF laboratories. These tests allow us to accurately

determine the temperature range of the SKF bearing greases given in the

selection charts included in this catalog.

The results of these tests are also used to evaluate the

grease life. The performance of each grease is then translated into a Grease

Performance Factor (GPF). Greases with highest values offer the longest life.

This factor, used in correlation with the SKF re–lubrication diagram (see SKF

General Catalog GC 5000), allows you to determine the correct

re–lubrication intervals for the chosen grease.

|

|

|

|

|

|

|

Re–lubrication intervals

Choosing the right bearing grease for a certain application is

critical to bearing performance. Applying the correct quantity of grease at

the right intervals is of equal importance. Over– or under–greasing as well

as inadequate lubrication methods can shorten the bearing’s service life. For

determining the right amount of grease and the correct re–lubrication

intervals for a specific application, SKF has developed DialSet, a simple

computerized re–lubrication calculation program. Calculated re–lubrication

intervals are based on the latest lubrication theories published in the SKF

General Catalog (GC 5000) and depend on bearing type used, application

conditions and properties of selected bearing grease.

|

|

|

|

The lubrication method used is equally important to the right

bearing grease, quantity and lubrication intervals. Using lubricators, manual

or automatic, facilitates proper lubricant supply to the application.

Maintaining cleanliness when lubricating bearings is crucial, as

contamination can cause the bearing to fail prematurely.

Using a grease meter in combination with a grease gun or pump

during manual lubrication helps ensure the supply of the right quantity of

grease. SKF’s range of grease guns, pumps and lubrication accessories is

designed for contamination–free grease supply as well as ease–of–use

Continuous lubrication using automatic lubricators, single or

multiple–point, provides the application with consistent and controlled

supply of bearing grease. This reduces the risk of over– or under–greasing

and positively contributes to optimizing the bearing’s service life.

Additionally, automatic re–lubrication reduces the risk of contamination.

Around the clock solutions offered by SKF, such as SYSTEM 24 and SYSTEM MultiPoint,

provide precise and reliable grease supply, exactly adjusted to the

application’s needs.

|