The velocity pickup is a very popular transducer

or sensor for monitoring the vibration of rotating machinery. This type of vibration

transducer installs easily on machines, and generally costs less than other sensors. For

these two reasons, this type of transducer is ideal for general purpose machine

applications. Velocity pickups have been used as vibration transducers on rotating

machines for a very long time, and they are still utilized for a variety of applications

today. Velocity pickups are available in many different physical configurations and output

sensitivities. The velocity pickup is a very popular transducer

or sensor for monitoring the vibration of rotating machinery. This type of vibration

transducer installs easily on machines, and generally costs less than other sensors. For

these two reasons, this type of transducer is ideal for general purpose machine

applications. Velocity pickups have been used as vibration transducers on rotating

machines for a very long time, and they are still utilized for a variety of applications

today. Velocity pickups are available in many different physical configurations and output

sensitivities.

Theory of Operation

When a coil of wire is moved through a magnetic field, a voltage is induced across the end

wires of the coil. The induced voltage is caused by the transferring of energy from the

flux field of the magnet to the wire coil. As the coil is forced through the magnetic

field by vibratory motion, a voltage signal representing the vibration is produced.

Signal Conventions

A velocity signal produced by vibratory motion is normally sinusoidal in nature. In other

words, in one cycle of vibration, the signal reaches a maximum value twice in one cycle.

The second maximum value is equal in magnitude to the first maximum value, but opposite in

direction. By definition velocity can be measured in only one direction. Therefore,

velocity measurements are typically expressed in zero to peak, RMS units. RMS units may be

specified on permanent monitor installations to allow correlation with information

gathered from portable data collectors.

Another convention to consider is that motion towards the bottom of a velocity

transducer will generate a positive going output signal. In other words, if the transducer

is held in its sensitive axis and the base is tapped, the output signal will go positive

when it is initially tapped.

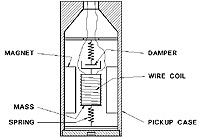

Construction

The velocity pickup is a self-generating sensor requiring no external devices to produce a

vibration signal. This type of sensor is made up of three components: a

permanent magnet, a coil of wire, and spring supports for the coil of wire. The pickup is

filled with an oil to dampen the spring action. The velocity pickup is a self-generating sensor requiring no external devices to produce a

vibration signal. This type of sensor is made up of three components: a

permanent magnet, a coil of wire, and spring supports for the coil of wire. The pickup is

filled with an oil to dampen the spring action.

Due to gravity forces, velocity transducers are manufactured differently for horizontal

or vertical axis mounting. With this in mind, the velocity sensor will have a sensitive

axis that must be considered when applying these sensors to rotating machinery. Velocity

sensors are also susceptible to cross axis vibration, which if great enough may damage a

velocity sensor.

Wire is wound onto a hollow bobbin to form the wire coil. Sometimes, the wire coil is

counter wound (wound one direction and then in the opposite direction) to counteract

external electrical fields. The bobbin is supported by thin, flat springs to position it

accurately in the permanent magnet's field.

Special Considerations

Number of Sensors

All vibration sensors measure motion along their major axis. This fact should be

considered in choosing the number of sensors. Due to the structural asymmetry of machine

cases, the vibration signals in the three axes of motion may differ. Where practical, a

velocity sensor should be mounted in the vertical, horizontal, and axial planes to measure

vibration in the three directions. The three sensors will provide a complete definition of

the vibration signature.

Mounting

For the best frequency response, the mounting location must be flat and 10% larger than

the velocity pickup, or if used a separate mounting enclosure. The surface will require

drilling and tapping to accommodate the mounting of the sensor.

Sensitivity

Some velocity pickups have the highest output sensitivities of any vibration pickup for

rotating machine applications. The sensitivity will vary from manufacturer to

manufacturer. The higher output sensitivity is useful in situations where induced

electrical noise is a problem. The larger signal for a given vibration level will be less

influenced by the noise level. Some velocity pickups with their sensitivities are listed

below:

| Sensitivity |

| STI

CMCPWIL793V |

100 mv/in/sec |

Frequency Response

Velocity pickups will have differing frequency responses depending on the manufacturer.

However, most pickups have a frequency response range in the order of 10 to 1000 hz. This

is an important consideration when selecting a velocity pickup for a rotating machine

application. The pickup's frequency response must be within the expected vibration

frequencies of the machine. Due to the support spring for the bobbin, a natural

mechanical resonance occurs at the low end of the frequency response curve. This resonance

is either damped by the oil contained within the sensor, or with a shunt resistor across

the coil's leads.

Calibration

No calibration of the velocity pickup is necessary, however, on an annual basis the sensor

should be removed from service for a calibration verification. Verification is required

because velocity pickups are the only industrial vibration sensor which has internal

moving parts that are subject to fatigue failure.

This verification should include a sensitivity response versus frequency test. This

test will determine if the internal springs and damping system have degraded due to heat

and vibration. This test should be conducted with a shake table capable of variable

amplitude and frequency testing.

Instrument Wire

The following table is a partial list of BeldenŽ Cables that should be used for the

instrument field wiring. These part numbers may be cross referenced to equivalent cables

from other manufacturers. The listed cables are polyethylene insulated, twisted, with

Beldfoil shield, drain wire, and PVC jacket.

| BeldenŽ Part Numbers |

| P/N |

Nom. O.D. |

| 18 AWG |

8760 0.22" |

| 20 AWG |

8762 0.20" |

| 22 AWG |

8761 0.18" |

Common Point Grounding

To prevent Ground Loops from creating system noise, system common, ground and instrument

wire shield must be connected to ground at one location only. In most cases, the

recommendation is to connect commons, grounds and shields at the Monitor location. This

means that all commons, grounds, and shields must be floated or not connected at the

machine.

Occasionally, due to installation methods, instrument wire shields are connected to

ground at the machine case and not at the monitor. In this case, all of the instrument

wire shields must be floated or not connected at the monitor.

Conduit

Dedicated rigid conduit should be provided in all installations for mechanical and noise

protection. The conduit should be metal, and in direct contact with each segment. All

metal junction boxes and fittings should be in direct contact with the conduit. With this

type of installation, a single ground point can be established.

To facilitate removal of the velocity pickup, a junction box with a barrier terminal

strip should be located close to the transducer. The rigid conduit should be attached to

the junction box and the final run to the pickup can be metal flexible conduit.

Velocity Pickup Checklist

- Velocity Sensor Type

- Number of Sensors

- Sensitivity

- Frequency Range

- Correct Instrument Wire

- Rigid Conduit

- Grounding

- Location(s) Documented

- Calibration Check

|